Understanding BLTouch and Its Importance

The BLTouch is an incredibly useful add-on for 3D printers, enhancing the accuracy and ease of bed leveling. This guide will take you through the process of BLTouch wiring for the Tevo Tarantula, a popular and affordable 3D printer. By adding a BLTouch, you can automate the bed leveling process, leading to better first-layer adhesion and overall print quality. This eliminates the need for manual bed leveling, saving time and reducing frustration, especially for beginners. This advanced sensor detects the print bed’s surface and automatically adjusts the nozzle height during printing, compensating for any imperfections or slight variations in the bed’s surface. Properly installed BLTouch simplifies the printing process and contributes significantly to the success of your 3D prints.

BLTouch Basics

The BLTouch is a type of auto-bed leveling (ABL) sensor that uses a combination of a probe, solenoid, and Hall effect sensor. When triggered, the probe extends downwards to touch the print bed. The Hall effect sensor detects the probe’s position and sends signals to the printer’s mainboard. The mainboard then uses this information to determine the distance between the nozzle and the bed at multiple points, creating a mesh of the bed’s surface. This mesh is then used to compensate for any imperfections in the bed’s level during printing, ensuring that the nozzle maintains the correct distance from the bed throughout the print process. This results in improved first layer adhesion and better overall print quality, reducing the chances of warping or other print defects.

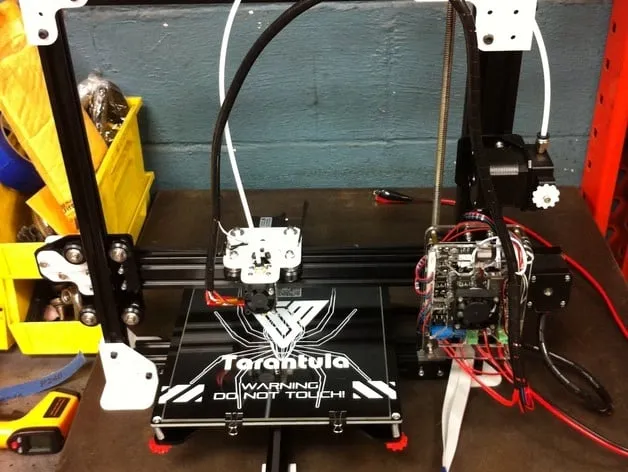

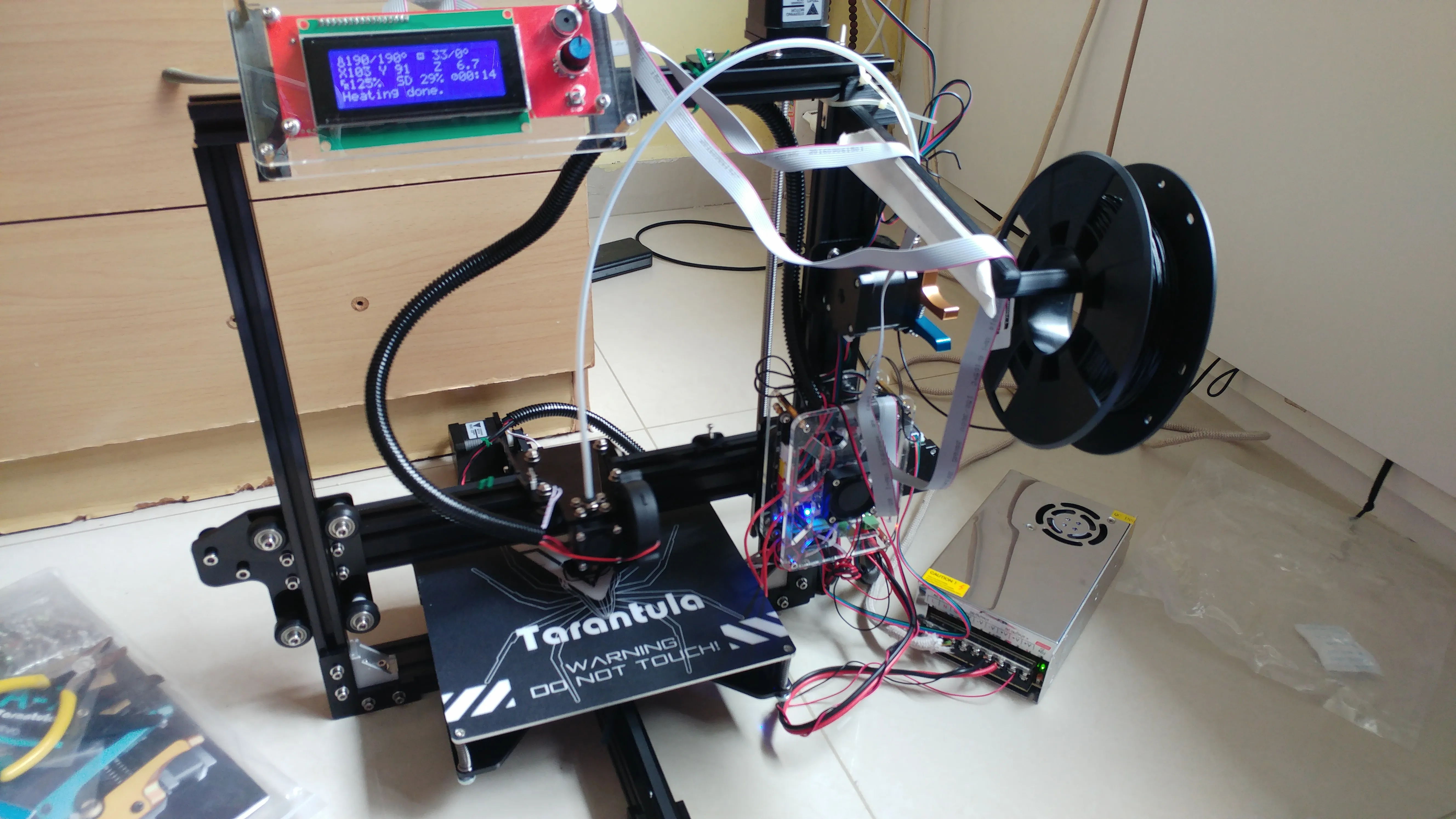

Why Use a BLTouch on Your Tevo Tarantula

The Tevo Tarantula, like many budget 3D printers, benefits greatly from the addition of a BLTouch. The printer’s bed leveling system can be somewhat challenging to adjust manually. A BLTouch simplifies this process by automating bed leveling. This automation reduces the need for frequent manual adjustments, making it more user-friendly, especially for new users. The ability to automatically compensate for bed imperfections helps ensures that the first layer adheres correctly to the bed. This is crucial for preventing common printing issues like warping and poor adhesion. Furthermore, a BLTouch increases the reliability and consistency of your prints and can significantly reduce print failures, leading to better print outcomes and a smoother printing experience. This is a worthwhile investment for any Tevo Tarantula owner seeking to improve their printer’s performance.

Tools and Materials You’ll Need

Essential Components

Before you begin, gather all the necessary components. First and foremost, you’ll need the BLTouch sensor itself. Make sure to purchase a genuine BLTouch and not a clone to ensure reliability. Next, you’ll need the correct mainboard connectors. You may need Dupont connectors and crimping tool. You will also need a suitable mounting bracket to attach the BLTouch to your Tevo Tarantula’s print head. This bracket is usually 3D-printed or purchased. Additional screws, nuts, and washers will be necessary to secure the BLTouch and bracket to your printer. Some kits may include these, but it’s always a good idea to have extras on hand. Lastly, ensure you have a microSD card or a way to transfer firmware to your printer’s mainboard.

Tools for the Job

You’ll also require several tools to complete the wiring and installation process. A small Phillips head screwdriver is essential for tightening screws. A multimeter can be useful for checking wiring continuity and diagnosing any potential electrical issues. Wire strippers and crimpers are necessary for preparing and connecting the wires correctly. A soldering iron might be needed if you need to extend or modify any wiring, although this is not usually required. You’ll need a 3D printer or access to one, if you plan to print the BLTouch mounting bracket. Finally, a computer with the Arduino IDE or similar software is required for uploading the firmware. Having these tools readily available ensures a smooth and efficient installation process. (See image: bltouch-components.webp)

Step-by-Step Wiring Instructions

Connecting the BLTouch to the Mainboard

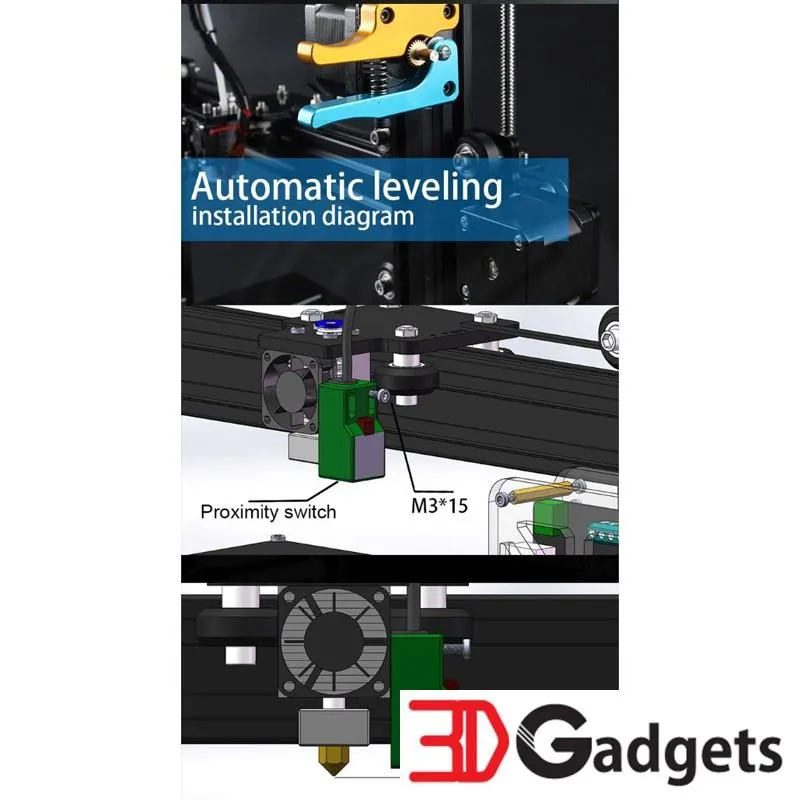

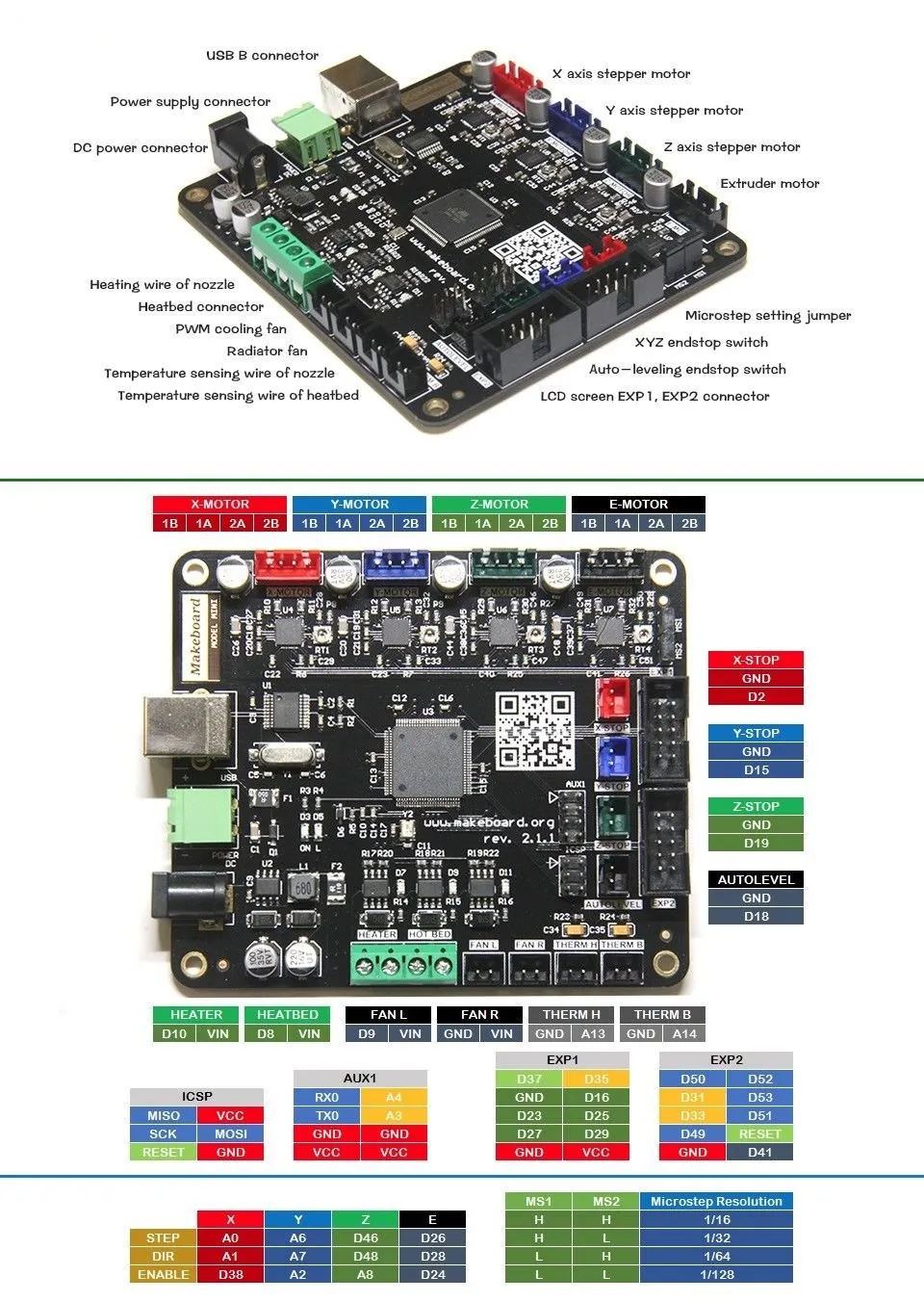

The most crucial step is connecting the BLTouch to the mainboard of your Tevo Tarantula. The BLTouch typically has three or five wires, depending on the version. Locate the mainboard on your Tevo Tarantula and identify the appropriate pins for connecting the BLTouch. The mainboard will have pins labeled for servo control (usually the servo pin), ground (GND), and 5V power. The remaining pins are for the Z-min endstop signal. Carefully insert the wires into the correct connectors on the mainboard, making sure to match the wire colors to the corresponding pins. The wiring diagram that came with your BLTouch will tell you what each color means. Ensure that the connections are secure and that the wires are not loose. A secure connection is vital for preventing the BLTouch from malfunctioning during the printing process. (See image: tevo-tarantula-mainboard.webp)

Wiring the Servo and Sensor Pins

The BLTouch uses servo and sensor pins for its operation. The servo pin is responsible for controlling the movement of the probe. This is the pin used to deploy and retract the probe. Make sure this pin is connected to the correct servo pin on your mainboard. The sensor pins provide information about the probe’s position and status. This tells the printer when the probe has contacted the bed and when to stop moving downwards. Double-check these wiring connections to make sure they are correctly aligned. Incorrect wiring can lead to the BLTouch not functioning correctly. Check the wiring multiple times before powering on the printer. This prevents damage to the BLTouch or the mainboard. (See image: bltouch-wiring-diagram.webp)

Verifying the Wiring Connections

Before powering on your printer, it’s important to verify all wiring connections to ensure that they are secure and correctly connected. Start by visually inspecting all the connections to make sure that all wires are properly inserted into the corresponding pins on the mainboard and that no wires are loose or damaged. You can gently tug on each wire to make sure it is firmly seated in the connector. You might also use a multimeter to check for continuity between the BLTouch and the mainboard, confirming that the wires are correctly transmitting the electrical signals. Make sure that you are confident that all wires are in the right location before moving forward. A mistake at this stage can be dangerous for your BLTouch and printer.

Firmware Configuration for BLTouch

Uploading the Firmware

Before you can use the BLTouch, you need to configure the firmware on your Tevo Tarantula. You will typically need to use a program like the Arduino IDE to upload the firmware to your mainboard. Download the latest version of Marlin firmware or your preferred firmware. Make sure to choose the correct configuration for your printer. In the Arduino IDE, open the configuration.h file. Here you will define the features of the BLTouch, bed size, and the printer model. After making your changes to the configuration files, compile the firmware. Then, connect your Tevo Tarantula to your computer via a USB cable. Select the correct board and port in the Arduino IDE. Finally, upload the compiled firmware to your printer’s mainboard, using the Arduino IDE or similar program. (See image: marlin-firmware-config.webp)

Configuring Marlin Firmware for BLTouch

In the Marlin firmware, you’ll need to enable several settings related to the BLTouch. First, enable the BLTouch option in the configuration.h file. This tells the firmware that a BLTouch is connected. You will also need to define the Z-probe offset. This is the distance between the nozzle and the BLTouch probe tip. To find the correct offset, you’ll need to measure and calibrate during the testing phase. Ensure that you have enabled the necessary bed leveling options, such as AUTO_BED_LEVELING_BILINEAR or AUTO_BED_LEVELING_UBL, in the firmware. Save the configuration.h file and upload the firmware to your Tevo Tarantula’s mainboard using the Arduino IDE. After the firmware is successfully uploaded, you will be able to start testing and calibrating your BLTouch.

Testing and Calibration

Leveling the Bed with BLTouch

Once the BLTouch is wired, the firmware is configured, and the firmware is uploaded, it’s time to test and calibrate the system. Start by powering on the printer and allowing it to initialize. Then, use the printer’s control panel to move the nozzle and the BLTouch probe to the center of the bed. Start a bed leveling sequence from your printer’s control panel. The BLTouch probe should extend, touch the bed at multiple points, and then retract. Observe the probe’s movements to make sure they are smooth and consistent. Adjust the Z-offset in the firmware or through your printer’s control panel to ensure the nozzle is the correct distance from the bed during printing. The Z-offset determines the distance between the probe tip and the nozzle; this needs to be calibrated properly to get a perfect first layer. Print a test print, such as a single-layer square, to check for proper bed adhesion and nozzle height. (See image: bltouch-calibration.webp)

Troubleshooting Common Wiring Issues

Sensor Not Deploying or Retracting

If the BLTouch probe is not deploying or retracting, the first thing to check is the wiring. Make sure the servo wires are connected correctly and are not reversed. Confirm that the power supply is delivering the required voltage. Verify that the firmware configuration is correct, with the BLTouch option enabled. Double-check the wiring connections to the mainboard. Another common issue is a faulty BLTouch sensor. If all the wiring and firmware settings are correct, try replacing the BLTouch sensor to see if it resolves the issue. Examine the probe itself for any physical damage or obstructions. This step will determine if the problem is with the sensor or with the wiring, which can save time during the troubleshooting process. (See image: bltouch-troubleshooting.webp)

Incorrect Z-Offset

The Z-offset is the distance between the nozzle and the bed when the BLTouch probe triggers. An incorrect Z-offset can result in the nozzle being too close or too far from the bed, leading to poor print adhesion. To fix this, you will need to fine-tune the Z-offset setting in the firmware. Start by manually leveling the bed. Then, move the nozzle to the center of the bed, and lower the Z-axis until the nozzle is almost touching the bed. Once the nozzle is in place, use the printer’s control panel to adjust the Z-offset in very small increments. Test your setting by printing a single-layer square and checking the first layer adhesion. The ideal Z-offset ensures that the filament is slightly compressed on the bed but not so much that the nozzle clogs or scratches the bed. Repeat until you achieve the correct Z-offset and a perfect first layer.

Final Thoughts and Next Steps

Congratulations! You’ve successfully wired and configured your BLTouch for your Tevo Tarantula. By following these steps, you’ve automated bed leveling, and improved the print quality. Remember to always check the wiring and firmware settings if you encounter any issues. Further tuning may be required to achieve the perfect first layer. If you want to dive deeper, research advanced bed leveling options and explore different printing techniques. Always stay updated with the latest firmware versions for your printer. Proper maintenance and regular checks ensure the longevity of your 3D printer and BLTouch sensor. Enjoy the enhanced print quality and the convenience that the BLTouch brings to your 3D printing experience. Happy printing!