What is Tarantula Dual Z and Why Upgrade?

The Tarantula 3D printer is a popular and affordable option for hobbyists and enthusiasts. However, like many entry-level 3D printers, it can benefit greatly from certain upgrades. One of the most significant upgrades is the installation of a dual Z-axis system. This system involves adding a second Z-axis motor and lead screw, effectively controlling the vertical movement of the print head from two points. This upgrade significantly improves the printer’s stability and print quality. The original Tarantula design uses a single Z-axis motor to lift the X-axis gantry, which can lead to several issues, especially on taller prints. A dual Z setup addresses these problems directly, making it a worthwhile modification for anyone looking to enhance their 3D printing experience. The upgrade provides a more robust and reliable printing platform.

Benefits of Upgrading to a Dual Z

Upgrading your Tarantula 3D printer to a dual Z-axis system offers a multitude of advantages. The primary benefit is a substantial improvement in print quality and reliability. By distributing the load across two Z-axis motors, the system minimizes the chances of the X-axis gantry tilting or binding. This leads to more consistent layer adhesion and a smoother overall surface finish on your prints. In addition, a dual Z system enhances the printer’s stability, especially during taller prints, which are prone to wobbling with a single Z-axis setup. The added stability reduces the risk of print failures, allowing you to create larger and more complex models with greater confidence. Furthermore, the reduced stress on the lead screws and motors extends the lifespan of your 3D printer components, providing a better overall user experience.

Improved Stability

The most immediate benefit of a dual Z upgrade is the marked improvement in the stability of your 3D printer. With two motors working in tandem, the X-axis gantry is supported more evenly, minimizing any tilting or swaying during printing. This is particularly crucial for taller prints, where the increased height can amplify any instability in the single Z-axis setup. The dual Z setup keeps the X-axis level throughout the entire print, producing more accurate dimensions and preventing layer shifting. The added stability results in a more consistent and predictable printing process, leading to fewer print failures and better overall print quality. The reduction in wobble allows for cleaner lines and sharper details, especially noticeable in detailed prints.

Enhanced Print Quality

The increased stability provided by a dual Z-axis system directly translates to enhanced print quality. By eliminating or minimizing the tilting of the X-axis, the printer ensures that each layer is deposited consistently and accurately. This precise layer alignment results in smoother surfaces, reduced layer lines, and overall improved aesthetics of your 3D prints. The consistent movement of the print head along the Z-axis allows for better adhesion between layers, leading to stronger and more durable prints. Details are rendered more crisply, and the finished product more closely resembles the intended design. This upgrade is especially beneficial for prints with complex geometries or intricate details, where even minor inconsistencies can have a significant impact on the final result.

Reduced Z-Axis Binding

Another critical advantage of the dual Z upgrade is the reduction of Z-axis binding. In a single Z-axis setup, the lead screw can sometimes bind, especially if it’s not perfectly aligned or if the X-axis gantry is heavy. This binding can cause inconsistent layer heights, leading to print defects. The dual Z system mitigates this issue by distributing the load more evenly and providing a more balanced lifting mechanism. With two lead screws working in unison, the gantry is less likely to experience binding, ensuring smooth and consistent vertical movement. This results in more accurate layer placement and a significant improvement in overall print quality. Eliminating binding also extends the lifespan of the lead screws and Z-axis motors, reducing the need for maintenance.

What You’ll Need

Before beginning the dual Z upgrade, ensure you have all the necessary components and tools. This will streamline the installation process and prevent any unexpected delays. The specific parts and tools required may vary depending on the dual Z kit you choose. However, here’s a general list to guide you through the preparation phase, making sure everything is ready before you start disassembling your 3D printer. Having everything on hand ensures a smooth and efficient upgrade experience.

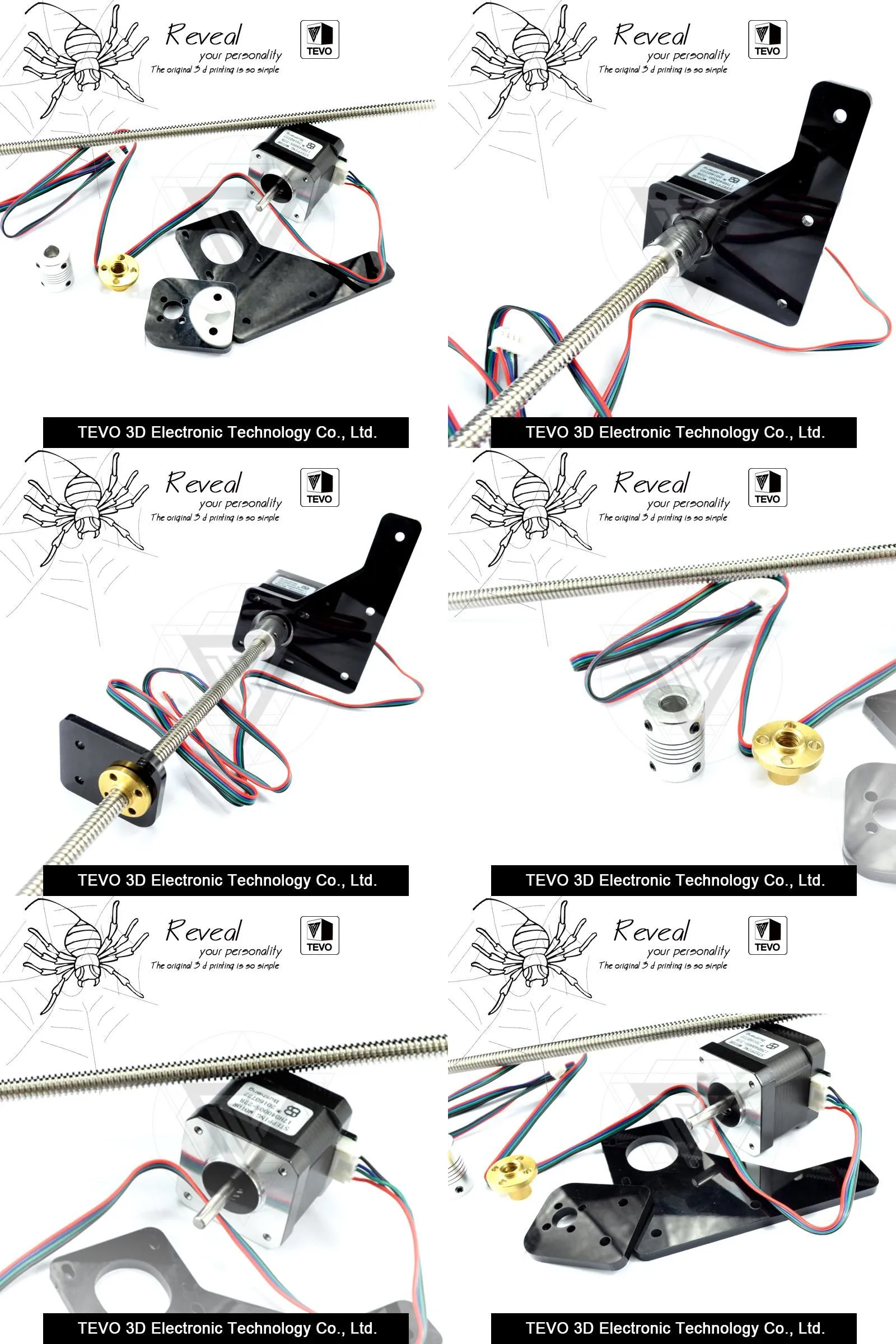

Dual Z Kit

The core component of the upgrade is a dual Z kit. This kit typically includes a second stepper motor, a lead screw, and the necessary brackets and hardware to mount the components to your printer. Many kits are specifically designed for the Tarantula, making installation straightforward. When purchasing a kit, consider the quality of the motors, lead screws, and brackets. Higher-quality components will provide better performance and longevity. Some kits also include a splitter cable to connect both Z motors to a single driver on your printer’s motherboard, simplifying the wiring process. Check reviews and ensure the kit you choose is compatible with your specific Tarantula model.

Tools

You will need several tools for the installation. A set of Allen wrenches or hex keys is essential for disassembling and reassembling your printer. A screwdriver set, including both Phillips head and flathead screwdrivers, will be necessary for removing and securing various components. You may also need a wrench to tighten the lead screws and other hardware. A multimeter can be useful for checking the wiring and ensuring the motors are correctly connected. Finally, having a pair of wire strippers and crimpers can be helpful if you need to modify or extend any wiring. A well-equipped toolkit will make the installation process much easier and more efficient.

Step-by-Step Installation Guide

Follow these steps to install the dual Z-axis system on your Tarantula 3D printer. This guide provides a general overview, and the specific steps may vary slightly depending on the kit you are using. Always refer to the instructions provided with your dual Z kit for precise guidance. Before starting, unplug your printer and ensure it is powered off. Proper preparation and following these steps will lead to a successful installation and a better 3D printing experience. Take your time, and double-check all connections and alignments.

Prepare Your Tarantula 3D Printer

Begin by powering off your 3D printer and unplugging it from the power outlet. This is a crucial safety step. Next, remove any prints from the bed and disassemble the printer to access the Z-axis components. This typically involves removing the X-axis gantry from the frame of the printer. Carefully detach the existing Z-axis motor and lead screw from the frame. It’s a good idea to take pictures of the existing setup before disassembling anything, to help you remember how everything goes back together. Organize the screws and parts to avoid any confusion during reassembly. This will give you clear access to the existing Z-axis mechanism and allow for the easy installation of the dual Z upgrade.

Mounting the Dual Z Motors

Attach the new Z-axis motors to the frame of your printer. The dual Z kit should provide brackets designed to mount the motors securely. Align the motors with the frame and use the appropriate screws to fasten them. Ensure the motors are positioned so that the lead screws can be easily connected. The mounting brackets are key to aligning the motors correctly. Ensure the motors are level and firmly attached to the frame. Proper alignment is crucial for the smooth operation of the Z-axis system and to prevent binding or wobble. Double-check that the motor is firmly secured before moving to the next step.

Connecting the Motors to the Z-Axis Lead Screws

Once the motors are mounted, connect the lead screws to the motor shafts. The kit will include couplers or connectors to join the lead screws to the motor shafts. Make sure the lead screws are parallel and properly aligned. Tighten the couplers or connectors to secure the lead screws. Ensure the lead screws move smoothly when rotated by hand. Carefully check that the lead screws rotate without binding. Any resistance or friction should be addressed before proceeding. The connection between the motors and the lead screws is critical for the Z-axis to function correctly, so take your time with this step.

Wiring the Motors to the Motherboard

Connect the Z-axis motors to the printer’s motherboard. Depending on your kit, you may need to use a splitter cable, or connect the second motor to a separate Z-axis driver if your motherboard has one. If your kit uses a splitter cable, plug it into the existing Z-axis motor connector on the motherboard, and then connect the two motors to the splitter. If using a separate driver, consult your motherboard documentation for the correct connections. Verify that the wiring is secure and correctly connected. Ensure that the polarity is correct to prevent motor damage. Check for any loose connections that could lead to malfunctions during printing. Proper wiring is essential for the motors to receive power and operate correctly.

Firmware Configuration and Calibration

After installing the dual Z-axis hardware, the next step is to configure and calibrate your printer’s firmware. This ensures that the printer recognizes and controls the two Z-axis motors correctly. Firmware configuration is often necessary to adjust the steps per millimeter for the Z-axis. Proper calibration and configuration of your firmware is essential for ensuring the dual Z-axis system works correctly.

Adjusting Z-Axis Endstops

Check and adjust the Z-axis endstops to ensure that the printer knows the correct home position for the Z-axis. The endstops tell the printer when the nozzle is at the lowest point. This is usually done by manually adjusting the endstop switches. Make sure that the Z-axis can reach the endstops without any obstruction. If the endstops are not properly set, the printer may not be able to home correctly, which will affect the printing accuracy and overall performance. Adjust the endstops so that the nozzle is just above the print bed when the Z-axis reaches its home position. This will make sure that the print bed is not damaged and the first layer is well-adhered to the print bed.

Leveling the Bed

Level the print bed to ensure the first layer of your print adheres correctly. This can be done manually by adjusting the bed-leveling screws or through the printer’s firmware if it supports auto-bed leveling. Proper bed leveling is crucial for good print quality. Run the bed leveling process to ensure the nozzle is the right distance from the bed. Use a piece of paper or a leveling gauge to ensure the nozzle is at the correct height. If your printer uses auto-bed leveling, follow the instructions in your printer’s manual. Leveling the bed correctly will ensure the best print quality and prevent adhesion problems. Make sure the bed is consistently level across the entire surface.

Testing the Dual Z System

After installing the dual Z-axis system and configuring the firmware, it’s essential to test it to ensure that it’s functioning correctly. This will allow you to identify and correct any issues before you begin printing. Testing the system is critical to verify that your modifications have been done correctly and to fine-tune your printer for the best possible performance. Printing a test object will enable you to observe how the dual Z-axis system is working and to make any necessary adjustments.

Troubleshooting Common Issues

Even with careful installation, you might encounter some issues with the dual Z-axis system. The following are some common problems and how to troubleshoot them. Knowing how to troubleshoot the issues that may occur can help you resolve them efficiently. Having a troubleshooting checklist will save time and improve the overall printing process. Keep these common issues in mind when setting up your dual Z-axis system.

Z-Axis Wobble

If you notice any wobble or instability in the Z-axis, first check the alignment of the lead screws and motors. Ensure that the lead screws are parallel and that the motor couplings are securely tightened. Also, make sure that the Z-axis rods are properly aligned and not bent. Check the frame of the printer to make sure it is stable and that all the screws are tightened. If the wobble persists, the lead screws might be bent or of poor quality, consider replacing them. Minor adjustments may also be required in the firmware. Adjusting the Z-axis motor current can also help to resolve this issue. Proper alignment and secure connections are key to eliminating wobble and instability.

Motor Not Moving

If one or both of the Z-axis motors are not moving, first check the wiring connections and make sure they are properly connected to the motherboard. Verify the motor driver settings and ensure they are correctly configured. Double-check the firmware settings for the Z-axis motors, especially the steps per millimeter. Test the motor’s driver to make sure it is working. Check the power supply. If one motor is not working, it could be faulty or that the driver is broken. If both motors are not working, the issue could be with the power supply or the motherboard. If the motors still do not move, consult the documentation for your 3D printer or the dual Z kit.

Conclusion

Upgrading your Tarantula 3D printer to a dual Z-axis system is a rewarding project that can significantly improve print quality, stability, and overall performance. This guide provides a comprehensive overview of the installation process, covering everything from preparation and hardware installation to firmware configuration and testing. By following these steps, you can transform your Tarantula printer into a more reliable and capable machine, enabling you to create higher-quality prints with greater ease. Always remember to refer to the instructions provided with your specific dual Z kit and take the time to troubleshoot any issues that may arise. Happy printing!