Understanding Layer Height in 3D Printing

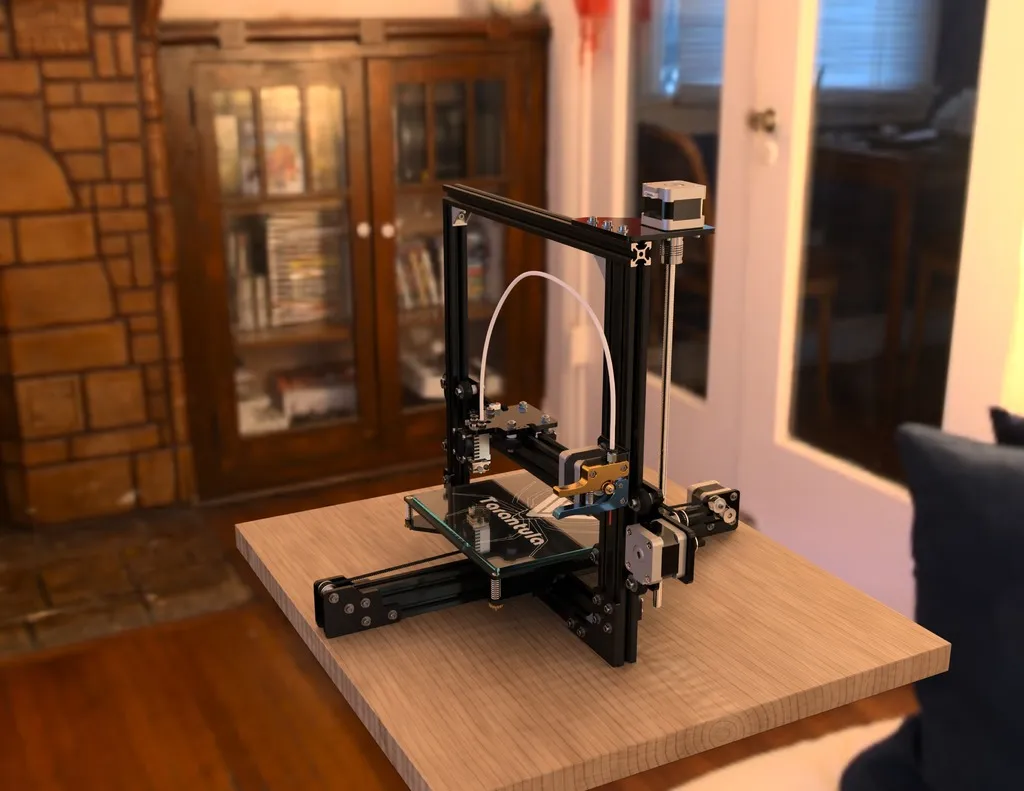

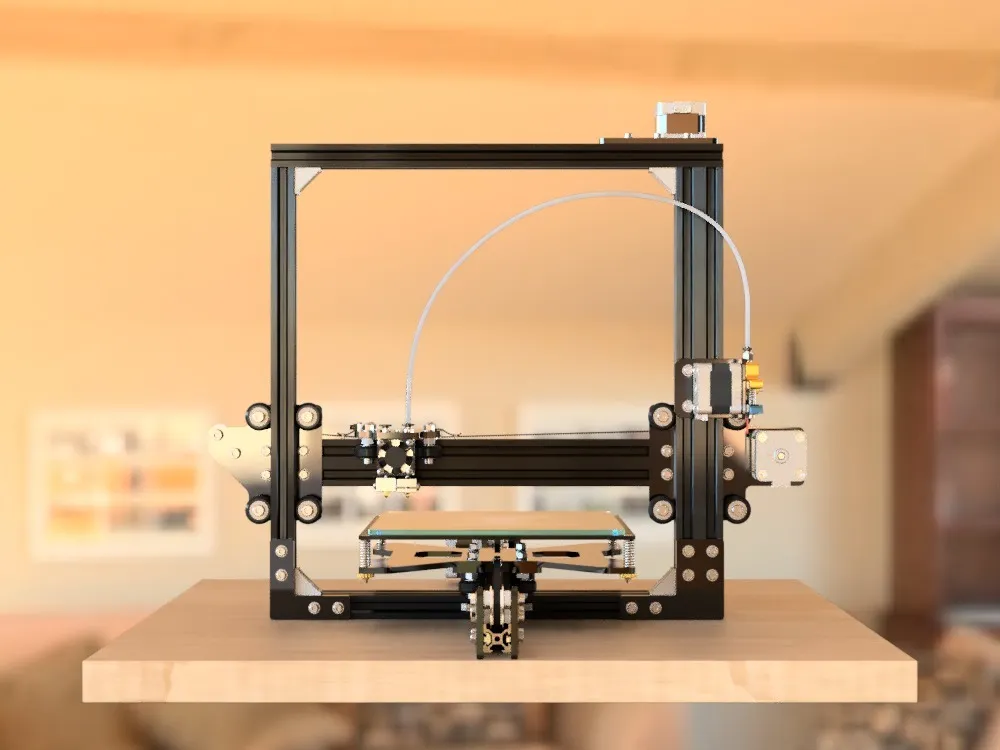

Layer height is a fundamental setting in 3D printing, especially when using a machine like the Tevo Tarantula. It directly impacts the quality, speed, and overall appearance of your printed objects. Essentially, layer height refers to the vertical distance your 3D printer’s nozzle moves with each pass, depositing a layer of filament on top of the previous one. This seemingly simple setting has a profound effect on the final outcome of your prints. Understanding how layer height functions and how to optimize it is crucial for achieving successful and high-quality prints with your Tevo Tarantula. This guide provides a comprehensive overview of layer height, its importance, and how to best utilize it for your projects. Proper layer height selection can be the difference between a stunningly detailed print and a failed, messy one.

The Importance of Layer Height

The layer height setting significantly influences several aspects of 3D printing. It affects the resolution and detail of the print, the time it takes to complete, and the overall structural integrity of the object. A lower layer height results in finer details and smoother surfaces because the layers are thinner and more closely packed together. Conversely, a higher layer height leads to faster prints, but at the expense of detail and surface finish. Finding the right balance between these factors is a key part of the 3D printing process. It allows you to customize prints based on your specific needs and available time. By mastering layer height settings, you can significantly improve the performance and quality of your Tevo Tarantula prints.

How Layer Height Affects Print Quality

Print quality is heavily influenced by layer height. When you use a lower layer height, the printed object will have smoother surfaces and finer details because the layers are much thinner. This is especially important for complex designs or parts where aesthetics are critical. However, lower layer heights also mean longer print times. Conversely, higher layer heights will result in faster print times but may show visible layer lines and a less refined surface. This is often acceptable for functional prints where dimensional accuracy is more important than aesthetic appeal. In summary, choosing the correct layer height is a trade-off between speed and quality. A good understanding of your projects needs is the key to selecting the right layer height.

Tevo Tarantula Layer Height Recommendations

The Tevo Tarantula, like other FDM (Fused Deposition Modeling) 3D printers, offers a range of possible layer heights. The optimal choice depends on the nozzle size, the type of filament being used, and the desired outcome of the print. A good starting point for most prints is between 0.1 mm and 0.3 mm. Experimentation is essential. The printer’s settings need to be adjusted based on the specific needs of the project at hand. For instance, a 0.2 mm layer height can often strike a good balance between detail and print time. Make sure to consider your specific requirements for each print. By carefully adjusting the layer height, you can significantly improve the quality and success rate of your 3D printing projects.

Optimal Layer Height Settings for Different Nozzle Sizes

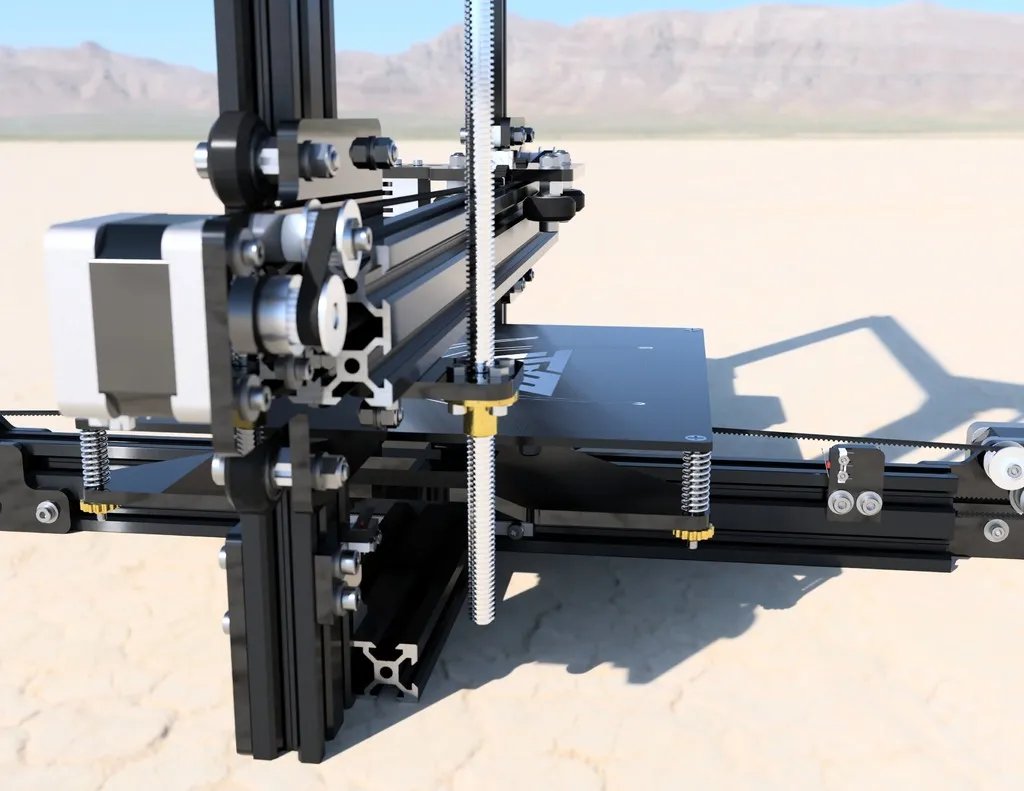

The nozzle size on your Tevo Tarantula greatly impacts the layer height settings you should choose. As a general rule, the layer height should be no more than 80% of your nozzle diameter. For example, if you’re using a 0.4 mm nozzle, you could use a layer height up to 0.32 mm. Using a smaller layer height allows you to achieve more detailed prints, while a larger layer height allows for faster printing. Smaller nozzles (0.2 mm or 0.3 mm) are excellent for detailed models with intricate designs, where a lower layer height like 0.1 mm or 0.15 mm might be ideal. Larger nozzles (0.6 mm or 0.8 mm) can handle larger layer heights (0.3 mm or higher) and are better suited for printing larger objects quickly, where fine details are not the primary concern. Choosing the correct nozzle size is essential for achieving optimum print quality.

Layer Height for Fine Detail Printing

For fine detail printing with your Tevo Tarantula, a lower layer height is essential. This is the key to capturing intricate features and achieving smooth surfaces. Aim for layer heights of 0.1 mm to 0.15 mm to get the best results. These settings will require more print time, but the added detail is well worth it for miniatures, figurines, or any object where appearance is important. It’s also important to carefully calibrate your printer and use a filament that’s suited for fine detail printing. Adjust the print speed to a lower setting, to ensure that the print head can properly deposit the filament and maintain the specified layer height. Patience is crucial in fine detail printing, but the results can be stunning and truly showcase the capabilities of your Tevo Tarantula.

Layer Height for Faster Printing

When speed is a priority, a higher layer height is the way to go. You can significantly reduce print times by using layer heights of 0.25 mm to 0.3 mm or even higher, depending on the nozzle size. This is especially useful for functional prints or prototypes where the visual finish is not as important. Keep in mind that the surface finish will be less refined, and layer lines will be more visible. You also want to make sure that your printer is well calibrated and that you’re using a filament that can be extruded quickly without causing problems. While the higher layer height will save time, it may also increase the chances of the print failing due to the increased filament flow and speed. The goal is always to balance speed with reliability.

Adjusting Layer Height in Your Slicer

Your 3D printer’s slicer software is where you control layer height. Programs such as Cura, Simplify3D, or PrusaSlicer allow you to set the layer height before you start printing. The process is usually straightforward. Simply select the layer height in the print settings menu. You can adjust it based on your project requirements. You will usually find presets or the option to manually enter the desired value. The slicer then converts your 3D model into G-code, which contains instructions for the printer, including the layer height. Remember to consider the nozzle size when selecting the layer height. It’s also advisable to test your settings on small test prints before printing the full model to ensure that the layer height is appropriate for the project.

Slicer Settings Explained

Beyond the layer height setting, other slicer settings influence print quality. These settings include the print speed, temperature, infill density, and support structure configuration. The print speed controls how fast the nozzle moves, and it should be adjusted based on the layer height. Slower speeds are usually necessary for lower layer heights to ensure that the filament adheres properly. The print temperature must be set according to the filament type used. Infill density impacts the strength and weight of the object, while support structures help to print overhanging parts. All of these settings work together. Therefore, understanding how to use and adjust them is essential for successful 3D printing. Experimenting with these settings will help you to fully unlock the potential of your Tevo Tarantula.

Troubleshooting Layer Height Issues

Even with careful settings, you may encounter issues related to layer height. Common problems include inconsistent layers, poor surface finishes, and print failures. Inconsistent layers can result from incorrect calibration, extruder problems, or unstable printing temperatures. Poor surface finish can be caused by too high a layer height or incorrect print speed. Print failures may occur if the layers do not adhere to each other properly. In cases of print failure, review your settings carefully and perform troubleshooting steps such as leveling the bed and checking your extrusion settings. A systematic approach to troubleshooting, combined with some trial and error, will help you identify and resolve any issues related to layer height and printing quality.

Common Problems

Layer height issues can manifest in several ways. You might observe visible layer lines, especially with higher layer heights. Another common problem is poor layer adhesion, which can result in the layers separating or the object crumbling. Other issues might involve stringing or oozing, which is often caused by incorrect temperature or retraction settings. Over-extrusion or under-extrusion can also affect layer height. These issues can be caused by the wrong layer height or a combination of other settings. Regular calibration and maintenance of your Tevo Tarantula, along with thorough investigation of the print settings, are essential to solve such problems. Take note of these issues as they arise and document the cause to enhance your print outcomes.

Solutions

Addressing layer height issues requires a methodical approach. Ensure that your printer is properly calibrated and that the print bed is level. Verify that the nozzle is clean and not clogged. Double-check your slicer settings. Print speed, temperature, and filament type settings must be matched with the layer height you have selected. If layer lines are visible, try reducing the layer height or decreasing the print speed. For poor layer adhesion, increase the print temperature slightly or clean the print bed to improve adhesion. Remember to conduct test prints with small models and fine-tune your settings before printing larger objects. By patiently experimenting with different settings, you can overcome most layer height-related problems and achieve the best possible prints with your Tevo Tarantula.

Post-Processing Considerations for Layer Height

The layer height you choose affects the post-processing steps. Objects printed with higher layer heights may need more sanding and finishing to remove visible layer lines and achieve a smooth surface. Those printed with lower layer heights may require less post-processing. However, regardless of the layer height, some post-processing steps may still be needed to create the desired aesthetic appearance. Planning your finishing process in advance can save you time and effort. Your printing expectations should be aligned with your desired surface finish. The choices you make with the layer height settings will influence the time and effort you invest in finishing your print. Be prepared to handle sanding, priming, painting, or applying surface treatments to enhance the final look of your printed model.

Sanding and Finishing

Sanding is a common post-processing step to smooth out the surfaces of 3D-printed objects. The sanding process helps to remove layer lines and imperfections. Start with a coarser grit sandpaper (e.g., 220-grit) to remove the bulk of the material, then progress to finer grits (e.g., 400, 600, 800) to achieve a smoother finish. Use wet sanding to minimize dust and generate smoother surfaces. After sanding, consider using a filler primer to fill in any remaining imperfections before painting. Proper sanding and finishing can significantly enhance the overall quality of your 3D prints, regardless of the layer height used. Sanding creates a much smoother surface that improves the appearance and durability of the finished product.

Painting and Surface Treatments

Painting can enhance the look of your 3D prints. Before painting, you should prime the surface. The priming step improves paint adhesion and provides a smooth surface. Use spray paint or brush-on paints, depending on the level of detail. For more complex projects, airbrushing can provide more control and better finishes. Besides painting, various surface treatments can enhance your prints. These treatments include applying epoxy resin for a glossy finish or using heat treatments to smooth the surface. When deciding on your paint and finish, ensure that it is compatible with the plastic used in your print. Choosing the correct paint and surface treatments will help to improve the aesthetic appearance and durability of your final product.