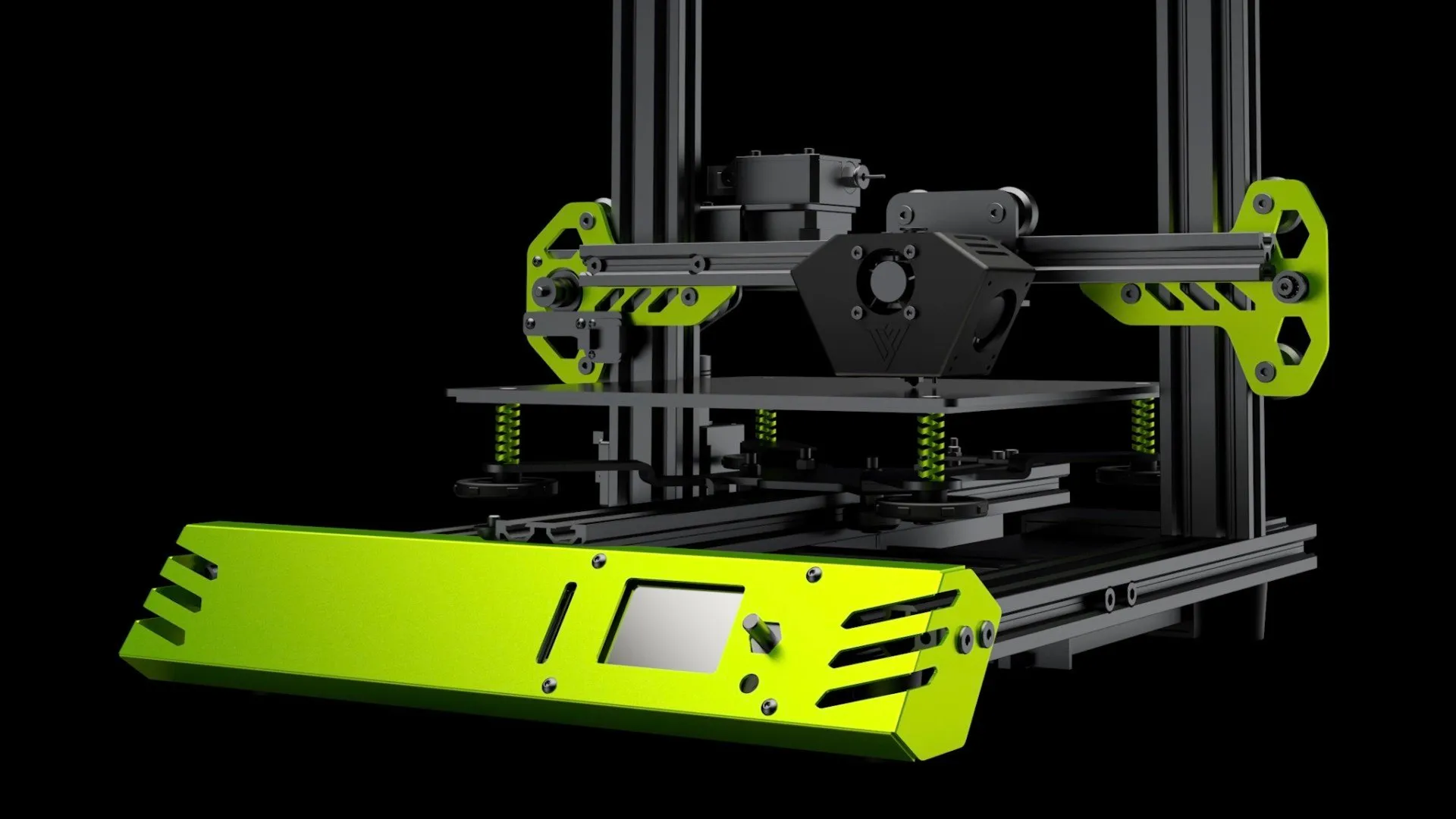

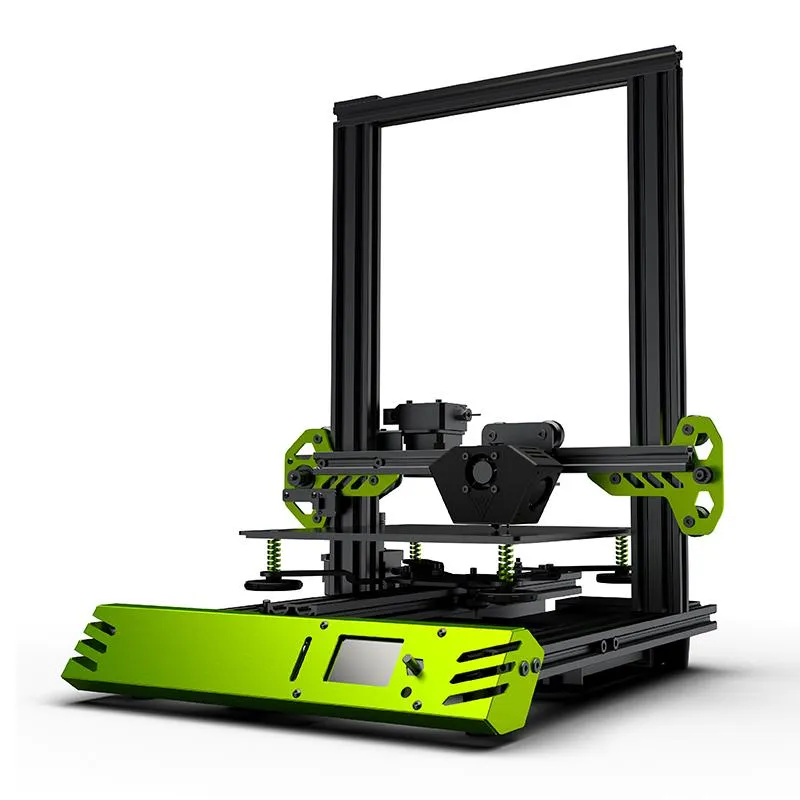

Why Upgrade Tevo Tarantula Pro with Linear Rails

The Tevo Tarantula Pro is a popular 3D printer, known for its affordability and ease of use. However, like any entry-level machine, there’s always room for improvement. One of the most significant upgrades you can perform is the installation of linear rails. This modification can drastically enhance your printer’s performance, leading to better prints and a more enjoyable printing experience. Linear rails replace the standard V-slot wheels, providing smoother, more precise movement along the axes. This upgrade directly addresses common issues found in printers with wheels, ultimately improving several aspects of printing.

Improved Print Quality

One of the most immediate benefits of upgrading to linear rails is a significant improvement in print quality. The smoother and more precise movement reduces the occurrence of layer shifting, ringing, and other artifacts that can mar the surface finish of your prints. By minimizing play and wobble in the print head and bed, linear rails allow for more accurate deposition of filament, resulting in sharper details and cleaner lines. This improvement is especially noticeable in prints with intricate designs or demanding tolerances.

Reduced Vibration and Noise

Vibrations are a common problem in 3D printers, especially during high-speed printing or when the printer is placed on an unstable surface. Linear rails are inherently more stable and absorb vibrations more effectively than wheel-based systems. This leads to a quieter printing experience, as the rattling and humming associated with wheel movement are greatly reduced. The quieter operation not only makes the printing process more pleasant but also contributes to higher print quality by minimizing the effects of vibrations on the printed object.

Increased Printing Speed

While the Tevo Tarantula Pro is not designed for incredibly high print speeds, linear rails enable faster and more consistent printing. The reduced friction and improved stability allow the print head and bed to move more quickly and accurately. This means you can increase print speeds without sacrificing print quality, thereby reducing overall print times. Keep in mind that other factors, such as the hotend’s ability to melt filament and the printer’s overall rigidity, will also play a role in determining the maximum achievable print speed.

Enhanced Stability and Precision

The robust design of linear rails contributes to increased stability and precision. They offer a more rigid platform for the print head and bed, minimizing flex and wobble during printing. This is particularly important for achieving accurate dimensions and maintaining consistent layer heights throughout the print. The enhanced stability also translates to better performance when printing with challenging materials, as the printer can better handle the stresses and forces involved in the printing process. This precision is important for larger prints, or parts that need to fit together.

What Are Linear Rails?

Linear rails, also known as linear guides, are precision components used to provide smooth, accurate linear motion. They consist of a rail and a carriage. The rail is a hardened steel track, and the carriage contains bearings that ride along the rail. This design allows for low-friction movement with minimal play or wobble. They are a significant upgrade over the standard wheels because wheels may develop flat spots, are prone to vibration, and lack the same level of precision. The implementation of linear rails increases the overall accuracy of the print head and the bed.

Components of a Linear Rail System

A typical linear rail system comprises several essential components. The rail itself is the foundational piece, providing the track for the carriage to move along. The carriage, which houses the bearings, glides along the rail, enabling smooth and precise linear motion. Depending on the design, the system may include end blocks, mounting hardware, and other accessories. The quality and precision of these components are key to achieving the desired performance and accuracy in 3D printing.

Types of Linear Rails

There are several types of linear rails available, with the most common being the miniature linear guide (MGN) series. These rails are compact, precise, and well-suited for 3D printer applications. Other options include profile rail guides, which offer higher load-bearing capabilities, and ball screw systems, which convert rotary motion into linear motion with high accuracy. The choice of linear rail type depends on the specific requirements of the 3D printer and the desired level of performance.

Top 5 Linear Rail Upgrades for Tevo Tarantula Pro

Choosing the right linear rail upgrade for your Tevo Tarantula Pro can be a game-changer. Here are five of the best options to consider, each offering different benefits in terms of cost, ease of installation, and performance.

MGN12H Rail and Carriage

The MGN12H rail and carriage is a popular choice for 3D printer upgrades due to its balance of performance and affordability. This type of rail is readily available and offers a good level of precision. The MGN12H system provides a significant improvement over the original wheels, reducing play and vibration. This setup is relatively straightforward to install on the Tevo Tarantula Pro, making it a good choice for beginners and experienced users alike.

Installation Guide MGN12H

Installing MGN12H rails typically involves removing the existing wheels and brackets, then attaching the rails and carriages to the appropriate axes. Precise alignment is crucial for optimal performance. You will need to measure carefully and make sure the rails are parallel to each other. Ensure the carriages move smoothly along the rails without binding. This process usually involves some adjustment and fine-tuning to achieve the best results.

Pros and Cons

The advantages of using MGN12H rails include improved print quality, reduced noise and vibration, and increased printing speed. The main drawback is the potential for needing to customize mounting solutions. Also, make sure to lubricate the rails and carriages to ensure smooth operation and longevity.

HIWIN MGN9H Rail and Carriage

HIWIN is a well-respected brand in the linear rail industry, known for producing high-quality, precision components. The MGN9H rail and carriage is a step up from the MGN12H, offering even greater accuracy and durability. This upgrade results in exceptional print quality, making it ideal for those who prioritize precision in their prints. Although HIWIN rails are often more expensive, the improved performance can be worth the investment for serious 3D printing enthusiasts.

Installation Guide HIWIN MGN9H

Installing HIWIN MGN9H rails follows a similar process to installing the MGN12H. You’ll need to remove the existing components and carefully mount the rails and carriages. HIWIN rails often come with very tight tolerances, so precise alignment is critical to avoid binding. Always check the carriage movement after installation, and make sure all screws are properly tightened.

Pros and Cons

The benefits of the HIWIN MGN9H are superior print quality and enhanced durability. The primary disadvantage is the higher cost compared to other options. Also, ensure proper lubrication and regular maintenance to extend the lifespan of the rails.

DIY Linear Rail Kits

For budget-conscious users or those who enjoy customization, DIY linear rail kits are an excellent option. These kits often include the rails, carriages, mounting hardware, and sometimes even instructions. They may require more assembly and modification to fit the Tevo Tarantula Pro, but they can save you money compared to pre-made solutions. Many online resources provide guidance and 3D-printable parts to help you install the rails.

Installation Guide DIY Linear Rail Kits

The installation of DIY kits varies depending on the specific design. You’ll likely need to modify or print brackets to secure the rails to your printer’s frame. Following the instructions provided with the kit and taking your time is essential. Ensure that all components are properly aligned and that the carriages move smoothly along the rails. Check online forums and communities for helpful tips and advice.

Pros and Cons

DIY kits are affordable and offer a high degree of customization. The drawbacks can be the increased installation time and the need for some technical skills. Print quality improvements will depend on the kit design and the quality of the components.

Belt-Driven Linear Rails

Belt-driven linear rails are a more advanced option, often used for the X and Y axes. They utilize a belt system to drive the carriages, allowing for fast and precise movement. These rails can significantly increase printing speed and reduce ringing artifacts. However, they require a more complex installation process and might need changes to the printer’s firmware.

Installation Guide Belt-Driven Linear Rails

Installing belt-driven linear rails involves removing the existing X and Y axis components and replacing them with the belt-driven system. You will need to mount the rails, install the belts, and adjust the tension. Precise alignment and belt tension are crucial for optimal performance. You may also need to adjust the stepper motor drivers and firmware settings to match the new system.

Pros and Cons

Belt-driven systems deliver higher printing speeds and improved print quality. The disadvantages include the more complex installation process and the need for firmware adjustments. Periodic belt tensioning and maintenance are also required.

Custom Linear Rail Systems

For those seeking the ultimate in performance and customization, building a custom linear rail system is an option. This involves designing and fabricating custom brackets, mounting plates, and other components. This approach allows you to tailor the upgrade to your specific needs and optimize every aspect of the system. A custom solution can result in top-tier performance and a truly unique 3D printer.

Installation Guide Custom Linear Rail Systems

Installing a custom linear rail system requires significant technical skills and access to tools such as a 3D printer, CNC machine, or other fabrication equipment. You’ll need to design and manufacture all the necessary components. Careful planning, precise measurements, and thorough testing are essential for a successful outcome. Because the system is custom, you will have to manage the installation of the entire system.

Pros and Cons

Custom systems offer the highest level of performance and customization. The drawbacks include the considerable time and effort involved in designing, fabricating, and installing the system. The cost can also be significant, depending on the components and tools required.

Installation and Configuration of Linear Rails

The installation of linear rails on your Tevo Tarantula Pro is not overly complex, but requires attention to detail. The general process involves removing the old components and carefully mounting the new linear rail system. Proper alignment and calibration are crucial for achieving the desired performance benefits. It is very important that your printer’s firmware is properly configured to support the new rails.

Tools and Materials Needed

Before you begin, gather all the necessary tools and materials. You will typically need a set of Allen wrenches, a screwdriver, a ruler or calipers for accurate measurements, and potentially a 3D printer for printing custom brackets. Make sure you have the correct linear rail kit and any accompanying hardware. Consider having some lubricant on hand to ensure smooth operation.

Step-by-Step Installation Guide

The installation steps will vary slightly depending on the linear rail kit you choose. Generally, the process involves removing the existing wheels and brackets from the axes you are upgrading. Then, install the new linear rails, ensuring they are perfectly aligned. Secure the carriages to the print head and bed. Tighten all screws securely. After installation, test the movement of the print head and bed to ensure it is smooth and free of any binding.

Firmware Configuration

After installing the linear rails, you may need to configure your printer’s firmware. This may include adjusting the steps per millimeter for the X, Y, and Z axes to account for any changes in belt or lead screw pitch. You may also need to calibrate your printer’s bed level and perform other adjustments to ensure optimal print quality. Make sure to backup your original firmware before making any changes. Also, check online resources for any specific information for your printer.

Maintenance and Troubleshooting

To keep your linear rail upgrade operating smoothly and to maximize its lifespan, regular maintenance is essential. You will also need to have some basic troubleshooting knowledge. Regular maintenance will ensure that your printer continues to perform well.

Regular Maintenance Tips

Regular maintenance helps the longevity of the rails. Lubricate the rails and carriages with a suitable lubricant. Check the screws for tightness. Keep the rails clean of any debris. If you hear any unusual noises, investigate the source. Following these simple tips can help prevent problems and maintain peak performance.

Troubleshooting Common Issues

Common issues include binding, excessive noise, and print quality problems. If the print head or bed is binding, check the alignment of the rails and carriages. If the printer is making excessive noise, check for loose screws or the need for lubrication. If you notice print quality problems, check the bed leveling and calibrate your printer’s settings. Consulting online communities and forums can also provide valuable guidance.

Conclusion

Upgrading your Tevo Tarantula Pro with linear rails is a rewarding modification that significantly improves print quality, stability, and printing speed. Whether you choose the affordable MGN12H, the high-precision HIWIN, a DIY kit, or a more advanced system, the benefits are clear. By following the installation guide and performing regular maintenance, you can transform your printer into a more capable and reliable machine. With linear rails, you’ll be able to print with greater precision and enjoy a smoother, quieter printing experience, allowing you to create even more complex and detailed 3D models.