Tevo Tarantula Setup Top 5 Must-Knows

Setting up your Tevo Tarantula 3D printer can be a rewarding experience, but it requires attention to detail. This guide will cover the top five essential aspects of the setup process, ensuring you get the best possible prints. From bed leveling to calibrating your extruder, each step is crucial for a successful print. Let’s dive into the key areas you need to master for optimal performance and print quality. Understanding these fundamentals will save you time, material, and frustration, allowing you to enjoy the exciting world of 3D printing. This article focuses on the critical steps to get your Tevo Tarantula up and running, helping you avoid common pitfalls and achieve fantastic results.

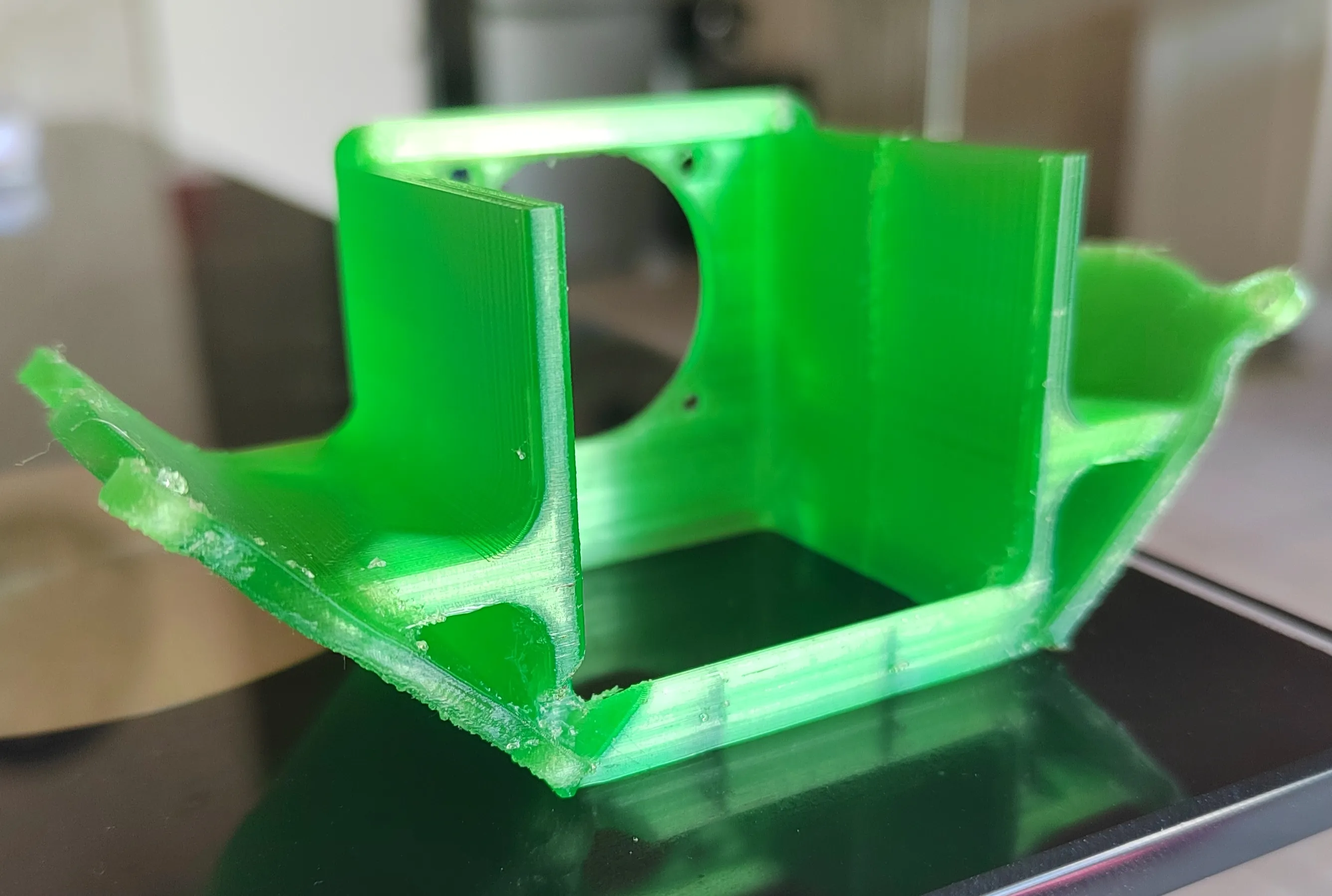

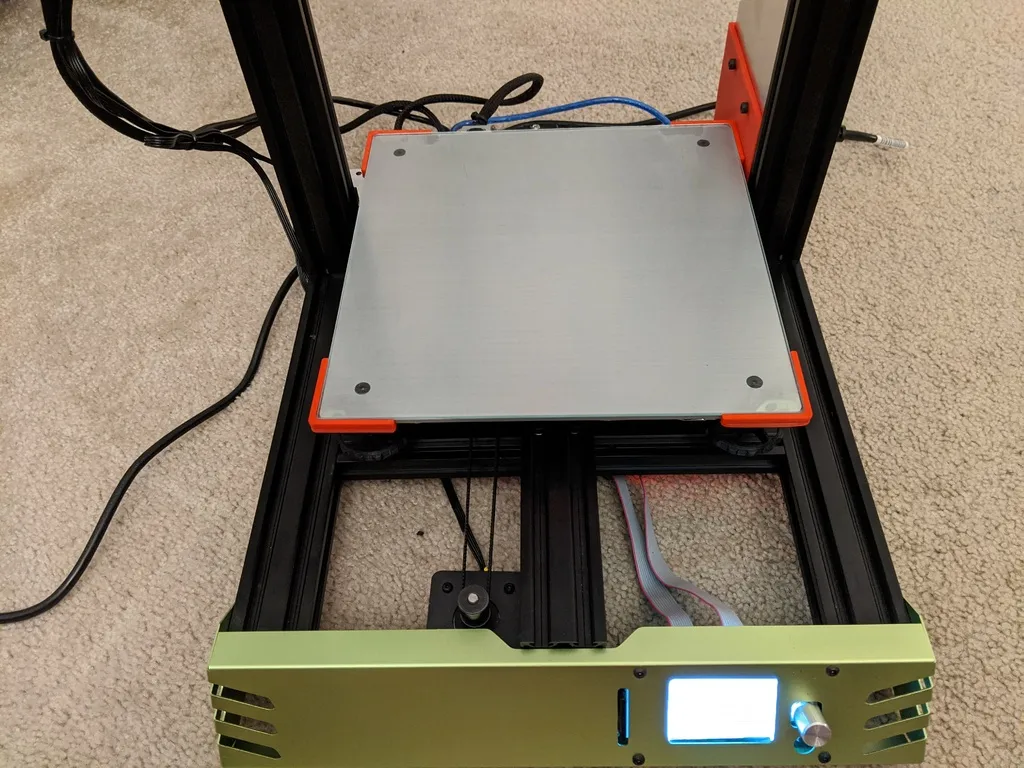

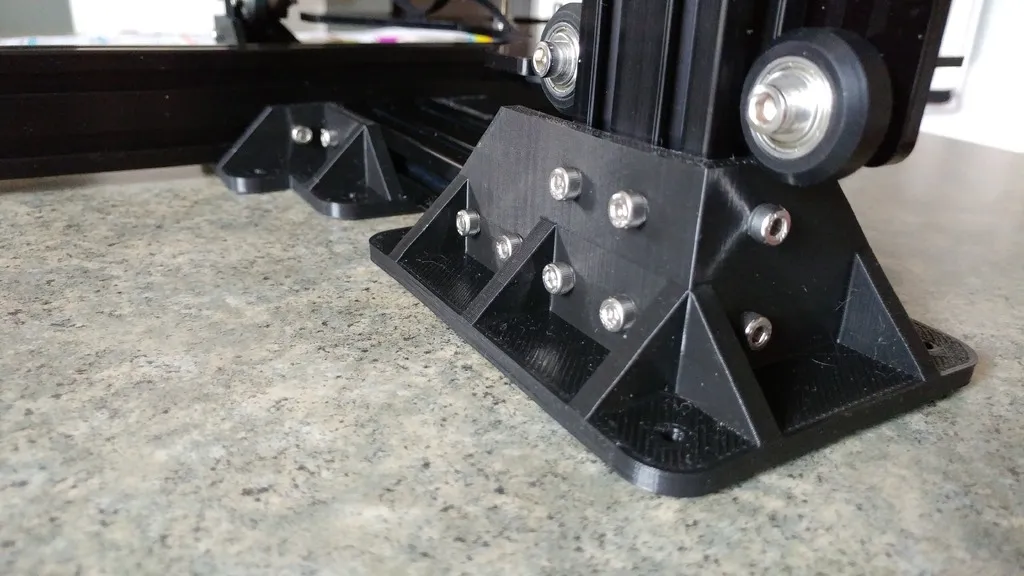

Leveling the Bed

Leveling the bed is the foundation of successful 3D printing. A properly leveled bed ensures the first layer adheres correctly, which is essential for the rest of the print. An uneven bed can lead to the nozzle being too close or too far from the printing surface, causing problems like poor adhesion, warping, or even damage to the bed or nozzle. The Tevo Tarantula typically uses manual bed leveling, requiring you to adjust the bed height at each corner using the leveling screws. Consistent bed leveling is vital for achieving quality prints, so take your time and ensure the bed is perfectly aligned before each print. Proper bed leveling prevents the nozzle from scraping against the bed, and guarantees the first layer adheres properly.

Manual Bed Leveling

Manual bed leveling involves adjusting the bed height at each corner using the leveling screws. Start by preheating your bed and nozzle to the temperatures you will use for your print, as thermal expansion can affect leveling. Place a piece of paper between the nozzle and the bed, then move the nozzle to each corner. Adjust the corresponding screw until the nozzle lightly grabs the paper, allowing you to feel a slight resistance when you move the paper. Repeat this process several times, going around the bed until all corners are level. Fine-tuning the bed level is crucial for the first layer’s success. You can also use a leveling probe for more precise adjustments. Regular checks and adjustments are often needed to maintain a perfectly level printing surface.

Adjusting Z-Offset

The Z-offset is the distance between the nozzle and the bed when the printer is at the Z-height of zero. It determines the correct height for the first layer. If the Z-offset is too high, the filament won’t stick to the bed, and the print will fail. If it is too low, the nozzle will scrape the bed, potentially damaging it and causing print defects. Setting the Z-offset correctly ensures that the first layer adheres properly and that the subsequent layers build upon a solid foundation. You can adjust the Z-offset during printing while observing the first layer. Fine-tune the Z-offset incrementally until the filament smoothly adheres to the bed without being squished or detached.

Setting Home Offsets

Home offsets define the printer’s zero position for each axis. Proper home offsets are essential because they ensure the printer knows where the edges of the bed are and where to start printing. The printer uses these offsets to determine where to move the nozzle for each print. If the home offsets are incorrect, the print may be misaligned, start outside the bed, or even crash into the frame. Setting the home offsets involves moving the print head to its home position and then telling the printer what that position is. This ensures that the printer accurately knows its starting point for all print jobs, contributing to better print quality and reliability.

X, Y, and Z Axis Home Offset

The X, Y, and Z-axis home offsets are the values that tell the printer where the origin (0,0,0) of the print area is located. They determine the position of the print head when the printer is homed. Typically, the endstops trigger when the print head reaches the end of each axis. The home offset then defines the exact position of the nozzle relative to the endstop. This is crucial for ensuring that prints start in the correct location. Incorrect offsets can cause the print to start outside the bed or to collide with the frame. You need to configure the home offsets in the printer’s firmware or through the control panel on the printer. Fine-tuning these offsets, by moving the nozzle over the bed using the control panel, ensures precise alignment and consistent printing results. Remember that these settings must be saved after adjustment.

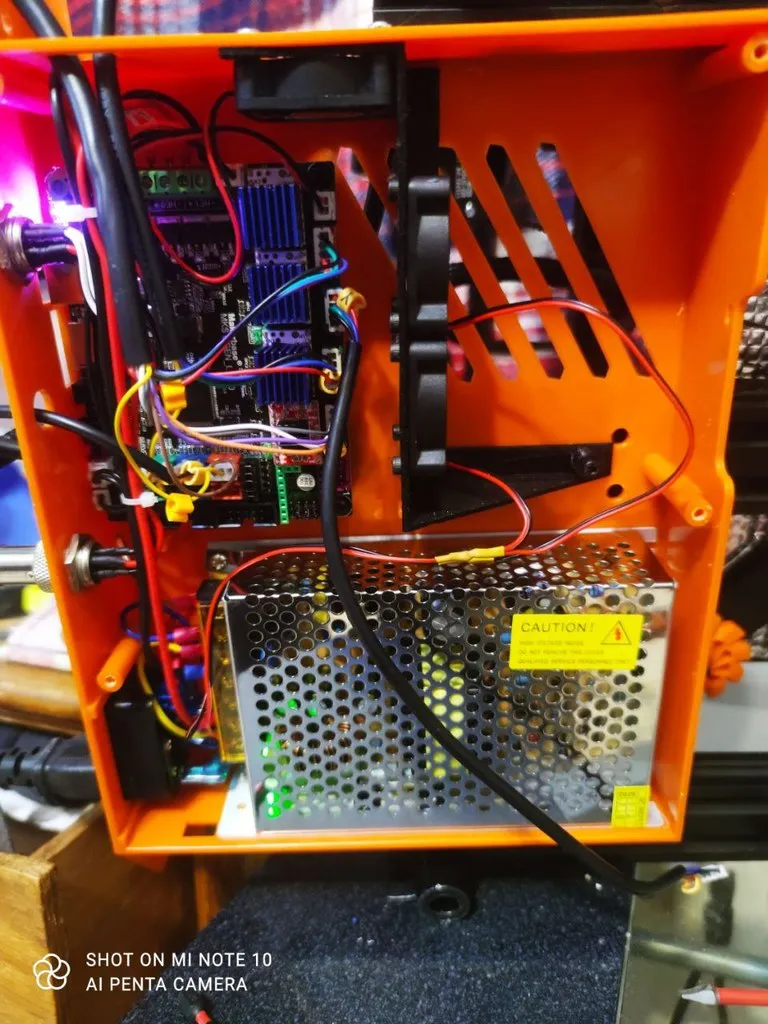

Adjusting Home Offset in Firmware

You can usually adjust home offsets through the printer’s firmware or using the control panel. Access the settings menu and look for options related to ‘Home Offsets’ or ‘Endstop Offsets.’ In the firmware, you might need to connect your printer to a computer and use software like Pronterface or Repetier-Host to send G-code commands. Use commands like ‘G92’ to set the offsets for each axis. Carefully move the print head to the desired home position, and then adjust the offset values until the nozzle is aligned with the bed. Save these settings to the printer’s EEPROM to make them permanent. Regularly check and update these settings to ensure accurate printing.

Optimizing First Layer Adhesion

First layer adhesion is critical for the success of your prints. Poor adhesion can lead to warping, detachment from the bed, and print failure. Proper bed leveling, Z-offset, and bed surface preparation are key to achieving good adhesion. Ensure your bed is clean, and consider using an adhesion aid like glue stick, hairspray, or painter’s tape for certain materials. The first layer should be slightly squished onto the bed to ensure good contact. Experiment with the bed temperature and nozzle temperature to find the optimal settings for your chosen filament. Slowing down the first layer printing speed can also improve adhesion. Proper adhesion prevents your print from detaching during the printing process, and is essential for overall print quality. This is frequently the cause of printing issues.

Adjusting the Nozzle Temperature

The correct nozzle temperature is essential for melting and extruding the filament properly. If the temperature is too low, the filament might not melt sufficiently, leading to under-extrusion and weak prints. If the temperature is too high, the filament can become too runny, causing stringing and oozing. Always consult the filament manufacturer’s recommended temperature range. Start with the lower end of the recommended range and gradually increase the temperature until the filament extrudes smoothly. Fine-tune the temperature based on the material, environmental conditions, and your printer’s performance. Ensure the temperature is consistent throughout the print. Proper nozzle temperature ensures that the filament melts and bonds correctly, producing strong, dimensionally accurate parts.

Calibrating Extruder Steps

Calibrating the extruder steps per millimeter (E-steps) is crucial for consistent extrusion. E-steps control how much filament the extruder pushes through the nozzle. Incorrect E-steps lead to over- or under-extrusion, affecting the print’s dimensional accuracy and strength. To calibrate, heat the nozzle, mark the filament 100mm from the extruder, and command the printer to extrude 100mm. Measure how much filament was actually extruded. Use the formula (actual extrusion / commanded extrusion) * current E-steps = new E-steps. Adjust the E-steps in your printer’s firmware and save the setting. Recalibrate whenever you change the extruder or modify the hardware. Accurate E-steps values guarantee that your printer extrudes the correct amount of filament, leading to well-defined and accurate prints. It will prevent print defects and enhance the printing process.

In conclusion, setting up your Tevo Tarantula involves several key steps, and by mastering bed leveling, Z-offset adjustment, home offsets, first-layer adhesion, nozzle temperature, and extruder calibration, you’ll be well on your way to printing success. Take your time, be patient, and experiment with the settings to get the best results. With the right setup, the Tevo Tarantula can produce amazing 3D prints. Proper setup is vital to enhance your 3D printing journey, and each step improves the printing experience. Enjoy the 3D printing!